Table of Contents:-

Technological Advances and Their Influence on Clutch Plate Prices

The Essential Function of Clutch Plates in Commercial Vehicles

The Rise of Advanced Materials in Clutch Plate Manufacturing

The Impact of Precision Engineering on Clutch Plate Costs

Automation and Robotics: A Double-Edged Sword for Pricing

The Influence of Market Dynamics and Supply Chain Factors

The Role of Research and Development in Pricing Strategies

The Future Outlook for Clutch Plate Prices

Upgrade Your Commercial Vehicle with Tata Genuine Parts

The automotive industry being dynamic has its challenges in the pricing of certain parts, such as clutch plates. Clutch plates, as an internal part of a commercial vehicle’s transmission system, are critical for the smooth shifting of gears and the effectiveness of the commercial vehicle. Owing to the ongoing changes in the methods of production as well as advances in the employed materials, changes in the price of the clutch plate have been notable. Here, we focus on how all these technological advancements have been able to shift the clutch plate price.

The Essential Function of Clutch Plates in Commercial Vehicles

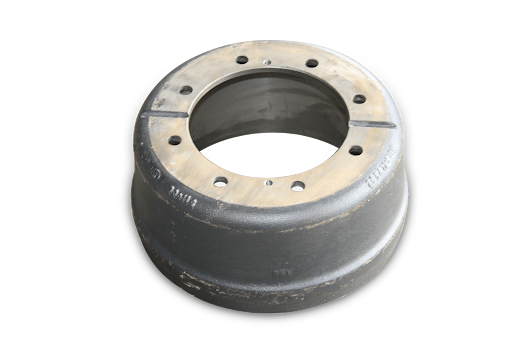

Clutch plates are vital for the efficient operation of a commercial vehicle’s transmission system. They connect the engine to the transmission, enabling the transfer of power to the wheels by engaging and disengaging the engine from the transmission. This process allows drivers to shift gears smoothly, maintaining the commercial vehicle’s momentum and preventing engine stalling. Due to their critical role, the quality and performance of clutch plates are directly linked to the commercial vehicle’s overall performance and lifespan. Therefore, the clutch plate price is a crucial factor for both manufacturers and consumers, as it reflects the quality, durability and reliability of the component.

The Rise of Advanced Materials in Clutch Plate Manufacturing

A breakthrough in making clutch plates is the use of better materials. In the past, clutch plates were made with basic material like asbestos, but that’s been phased out because it’s health concerns. These days, clutch plates are made with high-tech materials such as carbon composites, ceramics, and kevlar. Using these materials has an impact on the plates in several good ways. These materials offer several advantages, including enhanced durability, improved heat resistance, and reduced wear and tear, which contribute to a longer lifespan for the clutch plates.

Yet, using these cutting-edge materials has an impact on the clutch plate price. Carbon composite and ceramic clutch plates are common in high-performance and heavy-duty Tata Motors commercial vehicles because they can handle extreme heat and pressure. Making these materials is complex and costly, which shows up in the higher prices of the end product. Despite the increased cost, many consumers and manufacturers are willing to invest in these materials for the long-term benefits they provide, such as reduced maintenance needs and longer replacement intervals.

The Impact of Precision Engineering on Clutch Plate Costs

Another key factor that has an impact on the clutch plate price is how manufacturers use precision engineering. This means they apply cutting-edge tools like Computer-Aided Design (CAD) and Computer-Aided Manufacturing (CAM) to produce parts that are accurate and consistent. As a result, clutch plates fit just right in the transmission system, which lowers the chances of mechanical problems and boosts the car’s overall performance.

The use of precision engineering in making clutch plates has boosted product quality. However, this advancement also comes with increased production costs, as the technology and expertise required are expensive. The upfront cost of precision engineering can drive up the clutch plate price for high-end Tata Motors commercial vehicles where precision matters most. Still, as these methods become more common and manufacturing gets more efficient, the cost of precision-made clutch plates might drop over time leveling out prices.

Automation and Robotics: A Double-Edged Sword for Pricing

The introduction of automation and robotics into the manufacturing process has revolutionized the production of clutch plates. Automated systems and robotic technology have enhanced the consistency and quality of production, minimizing human error and increasing efficiency. This has led to a reduction in labor costs and faster production times, which could potentially lower the clutch plate price.

However, the initial cost of implementing automation and robotics is substantial. The investment in these advanced technologies can drive up production costs in the short term, which may be passed on to consumers in the form of higher prices. Over time, as manufacturers recover these initial costs and automation becomes more commonplace, the savings from reduced labor costs and increased efficiency could lead to more competitive pricing for clutch plates.

The Influence of Market Dynamics and Supply Chain Factors

The clutch plate price is also affected by market dynamics and supply chain factors. The demand for clutch plates varies depending on trends in the automotive industry, such as the shift towards electric vehicles (EVs) and hybrid technologies. As the industry evolves, the demand for traditional clutch plates may decline, potentially affecting prices. Conversely, the continued demand for high-performance vehicles and heavy-duty applications could drive up the price of specialized clutch plates.

Supply chain factors, such as the availability and cost of raw materials, transportation, and global economic conditions, also play a significant role in determining the clutch plate price. Disruptions in the supply chain, whether due to geopolitical tensions, natural disasters, or global pandemics, can lead to shortages of key materials and increase costs. These challenges highlight the importance of a stable and efficient supply chain in maintaining consistent pricing.

The Role of Research and Development in Pricing Strategies

Research and development (R&D) lead the way in tech breakthroughs for the automotive industry. Companies like Tata Motors invest heavily in R&D to come up with new ideas and make their products better all the time. This ongoing investment in new materials, manufacturing techniques, and product design is crucial for staying competitive in the market.

The Future Outlook for Clutch Plate Prices

As the automotive industry continues to advance, we can expect further innovations in clutch plate design and manufacturing. These changes will likely continue to influence the clutch plate price, with potential benefits for both manufacturers and consumers. As new technologies become more efficient and cost-effective, there may be opportunities for price stabilization or even reduction.

Moreover, as electric vehicles become more prevalent, the demand for traditional clutch plates may decrease, potentially leading to price adjustments. However, for those vehicles that continue to rely on internal combustion engines, the demand for high-quality clutch plates will remain strong. Companies like Tata Motors, through their Tata Genuine Parts division, are well-positioned to continue providing reliable and competitively priced clutch plates as the market evolves.

Upgrade Your Commercial Vehicle with Tata Genuine Parts

To ensure your Tata Motors commercial vehicle performs at its best, it’s essential to invest in high-quality components like clutch plates. TGP India offers a wide range of clutch plates designed with the latest technological advancements, ensuring durability and optimal performance.

Ready to upgrade? Visit our website or contact a Tata Motors distributor near you to explore our selection of clutch plates and other essential automotive components. With Tata Genuine Parts, you can trust that your Tata Motors commercial vehicle is equipped with the best parts, giving you peace of mind and enhancing your driving experience.

Understanding the impact of technological advances on clutch plate prices helps consumers make informed decisions about vehicle maintenance and upgrades. Trust Tata Genuine Parts for quality, reliability and competitive pricing.

Also Read:- Top 5 Essential Spare Parts for Tata Motors Commercial Vehicles and Their Functions